Mechanical Ventilation - General and at Source

Ventilation for Confined Spaces

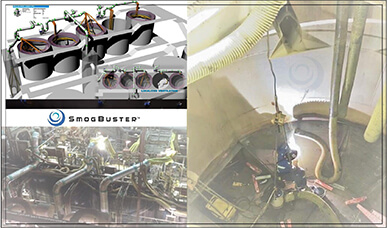

Ventilation for confined space work environments can be cumbersome and restrictive due to limitations in size, versatility and the need to schedule work in sequence to maintain air quality. Due to years of research and development, SmogBuster mechanical ventilation systems provide a solution to these typical issues.

Customized Temporary Ventilation Systems

The proper ventilation equipment for your confined space work environment makes all the difference in increasing production and lowering production costs. SmogBuster has invested heavily into customizing its temporary ventilation systems to create equipment that is not only versatile, but easier to move as required. Some of the benefits of these investments include:

- Spiral-wound aluminum in ducting to make it lightweight and easier to handle

- Proprietary rigid polymer collars to connect ducting and blowers that allow multiple configurations and fast assembly

- Backward inclined electric blowers designed to draw from varying access openings and long runs

- Localized ventilation adapters designed to meet and exceed standards for velocity and capture regulations

Increase your productivity with Mechanical Ventilation Service from SmogBuster

-

Experienced Ventilation Technicians

SmogBuster provides experienced ventilation technicians during shutdowns and for routine monitoring of equipment. During shutdown, they are available to limit interruptions due to reduced visibility, high LEL levels and other possible issues. They also provide measurable data for services rendered. During regular operation, equipment is checked and monitored on a routine basis to be sure optimal air quality is achieved.

Learn more about how SmogBuster customized mechanical ventilation solutions can greatly improve the production in your confined space work environment by contacting us.